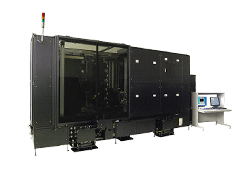

Mask Blanks Inspection and Review System

MAGICS Series M6640S/M6641S

Mask blank inspection system that achieve both high sensitivity and high throughput simultaneously

Topics

Features

- MAGICS series model featuring high sensitivity required for inspection of mask blanks as well as high throughput suitable for outgoing and incoming inspection of mask blanks in production.

- Multi-beam scanning method using 63 beams based on confocal optics, the core technology of the industry-standard MAGICS series inspection system.

- Special inspection circuitry attuned to detection of smallest defects.

- Inspection of pinhole defects on MoSi or Cr film with a dramatically higher sensitivity compared to the conventional system, enabling the selection of higher quality mask blanks.

- M6641S has an added capability to perform inspections in Dense Scan Mode (higher sensitivity mode) and Line & Space pattern inspections, thereby making an effective tool for various process management at mask shops.

- Applicable to a variety of cassettes including multiple-slot cassettes (for blanks manufacturers), RSP, and MRP (both for mask shops).

Applications

- Inspection of quartz substrates, Cr films, MoSi films, half-toned films, and resist-coated mask blanks

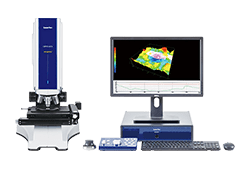

- Review of defects on these advanced mask blanks

Specifications

| Wavelength of Inspection light source used for inspection | 532nm |

|---|---|

| Inspection sensitivity | φ50 nm (PSL on quartz substrate, normal mode) |

| Inspection time | 12 minutes per plate (normal mode, Inspection area of 142 mm x 142 mm) |

| Applicable substrate | 6025 |