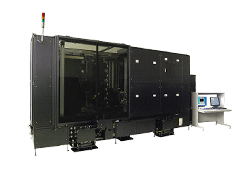

Pellicle Inspection and Pellicle Mounting System for CLIOS

51PA CM

Enabling the automated inspection and mounting of pellicles while linking with FPD photomask inspection system in the production line

Features

- This one system completes from inspection to tentative and final mounting of a pellicle.

- By connecting this system with CLIOS, particle adherence on photomasks and pellicles is remarkably reduced.

- Equipping of an ionizer keeps clean environment preventing particle adherence and prevents productivity deterioration caused by re-mounting of pellicles.

- The jigs for clamping a pellicle are stored in a stocker by different sizes and various sizes of pellicles can be appropriately processed, accordingly.

- Exfoliate paper is peeled off without excess stress due to detection of tensile strength at the clamping position when a pellicle is pulled out from the transport case.

- Alignment operation is available, while mounting a pellicle, by measuring the distance between the mask edges and pellicle edges by CCD cameras set at four positions.

- High operability is realized by equipping an automatic particle inspection function on a pellicle surface, a review function, a function to eliminate particles by Air Blow and a function to reverse the front and the back surfaces.

- This system works effectively for quality management and defective pellicle analysis, besides Good/No Good verification, because the detect particles can be observed either under bright view or under dark view and image data of particles can be storable.

- After tentatively mounting a pellicle on a photomask, the pillicle / photomask is transported to a nearby press machine. In the press machine, a number of sucking pads that utilize atmospheric pressure are installed at regular interval and final mounting of pellicle can be performed by application of constant pressure and time.

Applications

- Automated transfer and mounting of pellicles in FPD photomask production process

- Particle inspection on a pellicle surface by reflective scattering light (Quality verification inspection of a pellicle)

Specifications

| Pellicle size | 1146mm x 1366mm (1220mm x 1400mm Pellicle size for a mask) |

|---|---|

| Inspection speed | ≒50mm/sec |

| Inspection width | =180mm |

| Scattering light detector | Optical fiber coupling PTM* *Optical fiber coupling photo multiplier tube |

| Particle size for inspection | ≒10µm |

| Inspection area | Pellicle surface inside the pellicle frame by 5mm |

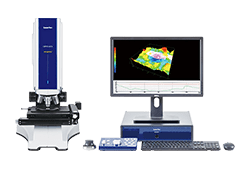

You might also be interested in