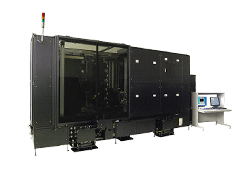

Automatic Inspection and Review System

OPTELICS AI²

Automatic defect inspection, high-magnification review, and 3D surface shape profiling all in a single device.

Topics

Features

- Automatic defect inspection, high-magnification review, and surface shape profiling of various types of semiconductor wafers, all in a single device that serves the varying needs of customers in their R&D and production processes

- High-speed inspection capability: inspecting a whole 3-inch wafer in 15 minutes with sub-micron sensitivity

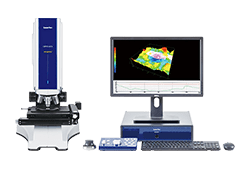

- High-magnification review capability: high-magnification surface shape profiling available with switching of objective lens

- Deep learning-based high-precision image classification, patterned sample inspection, and inspection of specific types of defects

- Defect inspection, high-magnification review, and surface shape profiling of transparent samples, such as compound semiconductors and films, without interference of backside reflection

- Lasertec providing a complete system including both hardware and software, making customization for specific need, and offering entire system support

Applications

- High-speed automatic defect inspection of various types of semiconductor wafers

- Defect review

- Defect surface shape profiling

- Defect tracking in production process

Specifications

| Inspection time (3" wafer) | 15 minutes per wafer |

|---|---|

| Samples | Various types of semiconductor wafers (including, silicon, SiC, GaN, InP, AIN and glass), glass substrates, films, and others |

| High-speed automatic surface defect inspection | Confocal and differential interference contrast optics |

| High-magnification defect review | Confocal optics |

| Defect shape 3D profiling |